PDF Version of Brochure (150 kb)

|

Bringing Asphalt Pavement

Technology Development

To Your Doorstep

US Department of Transportation Federal Highway Administration |

Purpose and Goals

The Federal Highway Administration''s (FHWA) Mobile Asphalt Pavement Mixture Laboratory (Mobile Asphalt Lab) is making it simpler for pavement engineers to gather data, test, and evaluate new technology development. To implement new technology, experienced technicians and engineers travel with the Mobile Asphalt Lab to project sites across the country, at the invitation of State highway agencies. Through the Mobile Asphalt Lab,FHWA aims to:

- Develop, test, evaluate, and implement Superpave® performance prediction tests on a national scale

- Work with transportation partners to resolve national issues related to implementation of new pavement technology

- Develop and support validation of performance-related construction specifications

- Provide input data to mechanistic-empirical pavement design procedure and evaluate asphalt distress models

| State |

Dates |

Location |

Project |

| Massachusetts |

October 6 - 29, 2004 |

Tauton |

Rt. 140 |

| Rhode Island |

in conjunction with Mass. |

N. Smithfield |

Rt. 146 |

| New York |

September 7 - 30, 2004 |

Albany |

NY Thruway |

| Minnesota |

August 5 - 31, 2004 |

Newport |

I-394 (I-35 & 5th St) |

| Kansas |

June-July 2004 |

Burns |

US-77 |

| Washington |

May 2004 |

Moses Lake |

I-90 |

| Louisiana |

April 2004 |

Baton Rouge |

US-120 |

| California |

December-January 2004 |

Downey |

N/A |

| North Carolina |

October-November 2003 |

Sanford |

Highway 87 |

| Maine |

September 2003 |

Bangor |

I-95 |

| Utah |

August 2003 |

Salt Lake City |

I-215, Legacy Parkway |

| Iowa |

July 2003 |

Charles City |

US-218 |

| Wisconsin |

June 2003 |

Waukesha |

I-894 |

| Arizona |

April 2003 |

Topock |

I-40 Rehabilitation |

| Special Projects |

| Wisconsin |

2004 |

Madison |

Perpetual Pavement |

| Pennsylvania |

2004 |

Blair County |

Site 7 - SISSI Project |

| Arizona |

2003 |

Flagstaff |

Forensic study |

| Florida |

2003 |

Gainesville |

HVS Test Track |

Development Activities

Improved Specifications

| "Successfully resolve national issues related to implementation of new pavement technology" |

The Mobile Asphalt Lab helps refine performance-related specifications (PRS), such as through fine-tuning test protocols and quality control/quality assurance (QC/QA) procedures.

New equipment is available to perform "shadow testing" validation of mix and aggregates at plants, laboratories, and construction sites, and the test data collected can helps to evaluate test repeatability and to refine test procedures.

|

Study of effects of lime in asphalt mixtures on performance |

The mobility of the laboratory facilitates data collection, testing, and evaluation at project sites.

Advanced Performance Testing

To predict performance, the Mobile Asphalt Lab evaluates new products. For example, field validation is conducted to identify and assess inputs to Mechanistic-Empirical Pavement Design Guide.

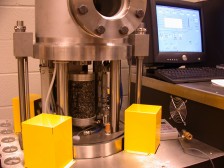

The lab is equipped with cutting-edge performance-testing equipment, such as the Superpave performance (SPT) tester that measures the dynamic modulus of an asphalt mix, and the aggregate video imaging system (AIMS) that determines fine and coarse aggregate shape, texture, and angularity. The Mobile Asphalt Lab also contains specimen fabrication equipment for the Superpave performance test. Specimens are compacted using a gyratory compactor which allows for compacting tall SPT specimens and is capable of measuring real-time shear resistance.

|

|

| Superpave performance test |

|

|

| Aggregate Imaging System |

Servopac gyratory compactor |

Conventional Testing

In the Mobile Asphalt Lab, technicians can conduct various conventional tests for asphalt pavement mix design including:

- Asphalt content by both methods

- Short- and long-term aging of hot-mix asphalt (HMA)

- HMA density by gyratory compactor

- Aggregate consensus properties

- Percentage of air voids in a compacted mix

- Apparent specific gravity, percent absorption (SSDetect, Corelok, T84)

- In-place HMA density by nuclear method

- Aggregate standard tests

- CoreDry

- Load Simulator, Hot Mix Simulator, RAM (no mix needed)

CoreDry |

RAM |

Load Simulator |

Hot Mix Simulator |

Working Together

The technical interaction among transportation personnel and on-site field testing encouraged by the Mobile Asphalt Lab benefits both FHWA and State and local agencies. One of the Mobile Asphalt Lab''s greatest assets is that it helps introduce new technology and test procedures into real-world construction. On-site activities can include:

- Validating equipment

- Evaluating asphalt mixes in field

- Introducing and implementing new performance-related specification standards

- Presenting materials at industry conferences, universities, and State and local highway agencies

- Evaluating new materials and pavement testing methodologies

- Publicizing materials in journals and conference proceedings

| QC/QA testing at FHWA Accelerated Load Facility |

|

|

Mix preparation conducted inside mobile trailer |

Contacts

If you are interested in the Mobile Asphalt Lab''s services, contact the FHWA Resource Center or your State''s FHWA Division Office. To reach the mobile asphalt laboratory staff directly, contact:

Matt Corrigan

FHWA Program Manager

(202)-366-1549

or

Chuck Paugh

Mobile Asphalt Pavement Project Manager

(202)-366-6640

Who to look for?

(from left): Brendan Morris, Josh Thompson, Jagan Gudimettla,

Chuck Paugh, Fazlitdin Shamsiev

U.S. Department of Transportation

Federal Highway Administration

Office of Pavement Technology

400 Seventh Street, SW

Washington, DC 20590

Publication No. F

® Reader®